As part of a SV/PRG Hardware Symposium, we polled the audience to see if they miss their product development schedule. Overwhelmingly, 85% of those polled stated that they had missed their product development schedule. Primary reasons cited for why they miss the schedule included the following:

Causes for Missing Hardware Development Schedule

When a hardware schedule is missed, it results in delayed shipments, miss-allocation of resources, and increased costs. These impacts ultimately cause potential buyers to find alternatives, investors to stop funding, and employees to change careers. Recent high profile examples where schedules were missed include Njoy (e-cig) $181M raised – ended in asset sale, JuicEro (juicer) $100M raised – ended in dissolution, and Pebble (wearables) $59M raised – ended in asset sale.

Panelists at a recent SV Hardware Startup-to-Scale Meetup on Accelerating Product Development discussed the importance of meeting the hardware schedule, and offered expert advice on what they have done to keep their development schedules on-track.

Panelists included:

- Robert Do, Senior Product Engineering Manager at Nutanix

- Mary Emerton, Vice President of Manufacturing at Nutanix

- Jay Feldis, Senior Technical Program Manager at PRG

- George Lewis, Director, Solutions Consulting at Arena Solutions

Managing the Hardware Project Development Schedule

Staying on schedule is the biggest challenge every new startup faces. The follow advice was offered by the panel to keep hardware schedules on track.

- Have a timeline in place, both for engineering and manufacturing, with appropriate buffers. As Mary Emerton explained, this helps set expectations of how it’s all going to go down.

- Get inputs from the whole organization; there should be tight interaction between the product and engineering teams.

- Create core development documents early, such as, product requirements documentation (PRD) and engineering development specifications (EDS)

- Leverage automated tools, such as Product Lifecycle Management (PLM) systems, so you can centralize your product data and your teams can be more efficient & effective.

- Use a structured phase-gate process for accountability from the development team to management about status and decisions as the product progresses through the commercialization process.

- Know what you’re good at, and know your gaps. Focus on core competencies — know when to leverage outside resources to meet schedules and mitigate risk. Who do you have in your network to help?

Flexibility vs. Control

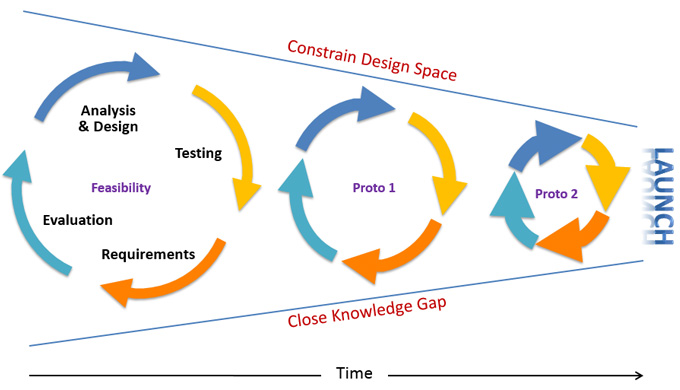

A strong new product development process strives to maintain greater flexibility early in development, and tighter controls as the product approaches scale.

- Limit the scope of the first release. Limited scope enables more flexibility and control. As Robert Do explains, it enables you to grow your team and your processes with more control.

- Get your platform for tools in place early, but don’t over-engineer and tie yourself down. Even with his bias for strong platforms, George Lewis acknowledges that you can always grow the platform incrementally, as business needs dictate. Even early on when a company is young and growing and wants to stay flexible:

- A company needs a set of anchor tools;

- A company needs a system of documenting and recording key decisions and facts

- Incorporate manufacturing inputs early into product design, for example about parts availability, scalability, and costs. This information should be documented, referenced and archived.

- Flexibility, like a funnel, has to narrow over time, especially as you get closer to manufacturing. According to Jay Feldis, “as you reach certain phases, you have to take certain flexibility off the table so that it will eventually converge to something that is very well defined for manufacturing.” You need to have a system of recording documents and facts and have basic tools in place.

Sustainability & Scalability

Mary Emerton, VP of Manufacturing at Nutanix, coaches her teams to build processes with scalability in mind. “I encourage my teams to think about what it will be when the volume will be 10 times what it is now. If they keep that in mind from the very beginning of the conversation, there is a very different outcome.”

- Look at things overall and what the endgame will be.

- Figure out your “core basics to make the business run.” These are the “boulders” that enable you to scale.

- Fill in the “boulders” with little extras, “pebbles,” for “flexibility” and “scalability.”

- Test! Set up a robust testing process that goes through all the normal variances for all your components.

- Automate your test, and incorporate test early in development.

- Supply chain management: select parts and suppliers with scalability in mind. Are you designing in parts that are easily available and not obsolete? Do you have multiple sources specified? Are costs in-line with targets? Will you still be able to get timely supplies of parts when you need 10 times or 1000 times more?

When to Leverage Outside Partners

It is important to know when to use outside partners to assist in your new product development. To properly evaluate this question, you must understand your core business and your core competencies.

- Hire internally to build your core and establish experts in those areas.

- Areas to use outside partners:

- To help accelerate a particular product

- Filling in skills gaps to meet your particular time frame or budget

- Caveat: Does the partner have the core competencies that you need? Make sure that it’s not a new area for that partner. The partner may want to develop this new area with you. However, the risk of failure and non-delivery by an inexperienced partner can set your product schedule back.

Best Practices Lead to Savings

Several best practices emerged from the panel to keep in mind.

- Know your core business.

- Create core documents early.

- Assign a dedicated Technical Program Manager (TPM) to drive the project and optimize resources.

- Install automated tools that are scalable.

- Follow a structured phase-gate process to address issues and mitigate risk at every stage of development.

- Allow greater flexibility earlier in development to foster creativity and move fast.

- Exercise tighter controls as you approach production, especially if you expect your product to ship on-time and scale rapidly.