What we did

PRG provided the company with our NPI solution, setting up a Product Life Cycle (PLC) process and a Product Lifecycle Management (PLM) system that enabled the company to scale quickly.

Results

The company established formalized PLC processes that enabled the acceleration of product development and improved communications, laying the foundation for sustained growth.

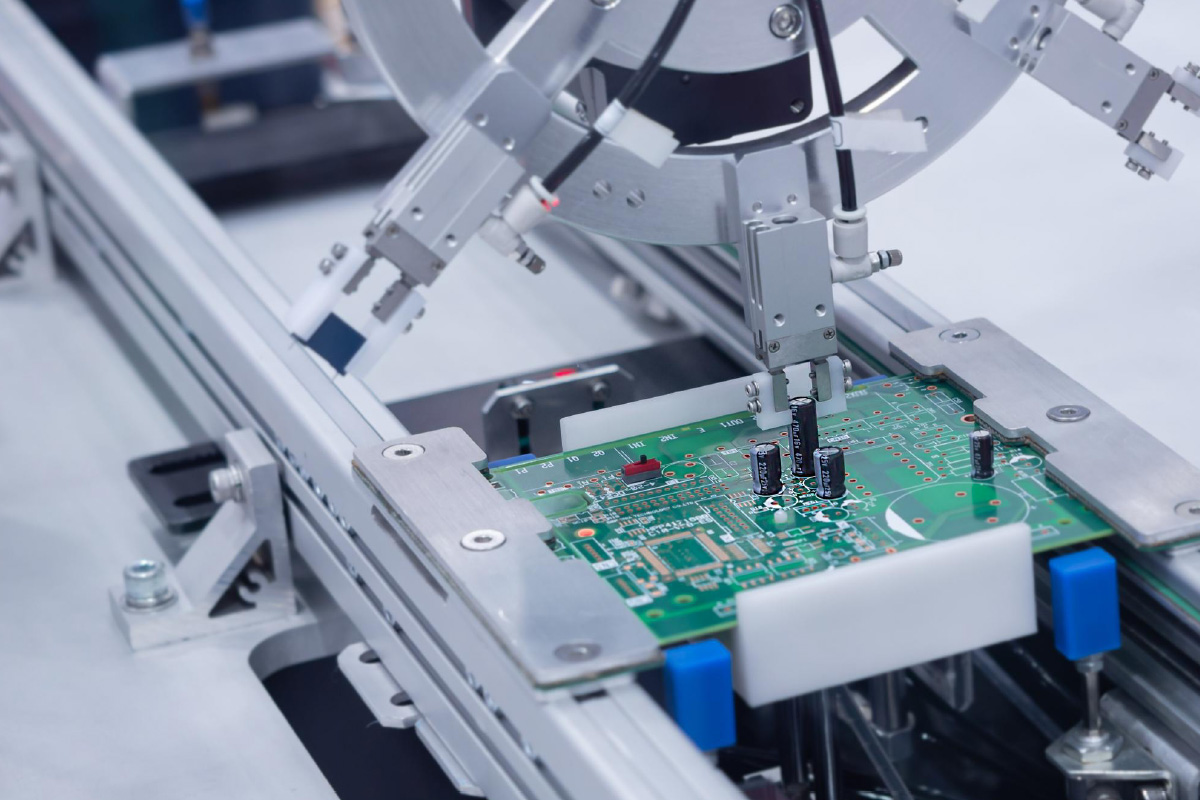

Company: A rapidly-growing robotics manufacturing company

Headquarters: USA

What they do: The company is rapidly growing in the desktop manufacturing space, with a proliferation of new products and accessories.

Challenge

Prior to 2017, the market for the company’s product was relatively small. But, over the 2018-2021 time period, the company grew extremely fast, with orders increasing over 400%. A lack of effective processes resulted in slipping schedules, exceeding development budgets, breakdowns

in communication, and a high number of post launch product changes. These issues had strained their relationships with development and manufacturing partners.

Solution

As a part of the NPI IMPACT solution, PRG provided a group of seasoned NPI process experts who delivered the following results

- Established a PLC process

- Negotiated a phase gate process with all stakeholders

- Setup a PLM system to manage parts, documentation, and engineering change management.

- Formalized Engineering Change Order (ECO) process

- Wrote key process documents in conjunction with stakeholders (e.g. ECO,quality, deviation, etc.) and supported the creation of product/market requirements documents

- Developed and executed company wide training programs that included design engineering, quality, manufacturing and other groups.

- Interim management of PLM functions .

Building a scalable foundation

This company’s senior management recognized the current way of operating was not sufficient to support the high growth that had taken place and was forecasted over the next couple of years.

The creation of a formal PLC process was essential because it provided a solid foundation to grow the business and provided the following benefits

- Improved product development process visibility

- Increased inter-departmental coordination

- Streamlined product development.

Creating transparency for agility

The adoption of a PLM process enabled the company to better manage product data and improve cross-functional communications. We created a protocol for the bill of materials (BOM), design documents, and Engineering change orders.

The company also rolled out company-wide training programs to ensure all managers and critical resources understood how to best use the new tools and applications. With a formal process in place, the company is now set up for success and able to scale its business for years to come.

PRG’s skilled team of engineers and consultants immediately brought value to the company without the time and cost of training new employees. Since deploying our new product, the remarkable improvements in quality and reliability have been truly transformative.

— Senior Director of Operations

The right people, processes, and relationships

PRG mobilized a broad team of experts to set up critical business systems that resulted in a robust development process, improved product quality, and a scalable business model.

Business systems expert

A senior product development and business systems professional led the selection, configuration, and deployment of new business systems and processes.

Quality systems engineer

A quality systems engineer provided expertise in quality programs to assess, develop, and deploy quality processes.

PLM experts

PRG’s experts set up a PLM system that enabled the company to more effectively manage products, parts, documentation, and product changes.

The final result

By leveraging PRG’s on-demand team of NPI IMPACT experts, the company was able to streamline product development, improve quality, and adopt business systems to successfully manage rapid growth.

Key benefits of engagement with PRG

- Accelerated product development schedule and reduced time-to-market

- Improved communication between all departments and external partners

- Reduced costs associated with development, manufacturing, rework, and parts scrap

- Creation of key documents to ensure repeatable processes

- Established business systems that enabled the company to scale quickly

- Enabled necessary controls to support regulatory compliance

DOWNLOAD

DOWNLOAD