At Project Realization Group, our technical program management team understands that lean product development might mean different things to different organizations. The term “lean” is often heard in the manufacturing, healthcare, and development industries. So, what does lean mean for you and the development of your electronic hardware product?

What Is Lean?

Lean processes were developed to add value and eliminate waste. To clarify, let’s start with the 5 main principles of a lean process and apply them to a product development enterprise. These principles include:

- Value – Understand, Identify & Specify

- The Value Stream – Fine Tune Your Processes

- Establish Flow – Eliminate Interruptions

- Pull – Back Flow With Customer Demand

- Continuously Eliminate Waste

The Goal Of Lean Product Development

Using these principles, our goal statement for a lean product development value stream for electronic device production can be summarized as follows:

“To develop products that maximize customer value and minimize product cost, in the least amount of time, and at the least amount of product development cost.”

What makes achieving this goal complicated, is that hardware product development determines both the value and the cost of not only your project and product, but the manufacturing process as well. This highlights the critical importance of having experienced hands involved during the entire product development process.

High-Level Objectives For Enterprises & Organizations

Using the lean product development goal statement above, we can derive some high-level objectives as follows:

- To better understand the customer (maximize customer value).

- To do the right projects (perform product, project and portfolio value analysis).

- To do our projects right (minimize redesign, waste and rework).

- To level load the organization (minimize bottlenecks and resource constraints).

- To create and re-use artifacts (standardize and sustain best practices).

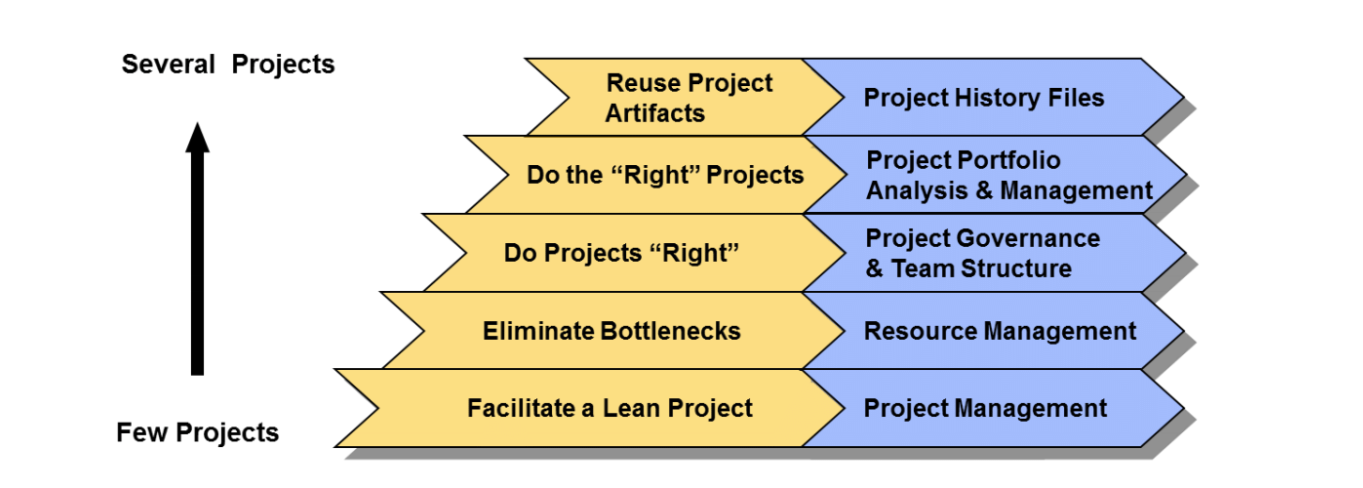

Let’s start by listing lean objectives based on the number of product development projects:

More projects generally require more governance and technical project management, including the proper managing of resources across projects.

More projects generally require more governance and technical project management, including the proper managing of resources across projects.

Several elements of lean product development are apparent:

- We follow a disciplined product development and project management process (standard work).

- We reduce bottlenecks by effectively managing resources.

- We eliminate rogue projects-cancel projects that no longer make business sense.

- We reduce work-effort on the wrong projects.

Note an element of ‘slowing-down-to-go-faster’ here. We are investing work-effort in technical project management to achieve significant savings, and enable more valuable projects to be completed faster. This reduces waste and increases both quality and profitability overall.

Lean Production For Startups & Commercialization

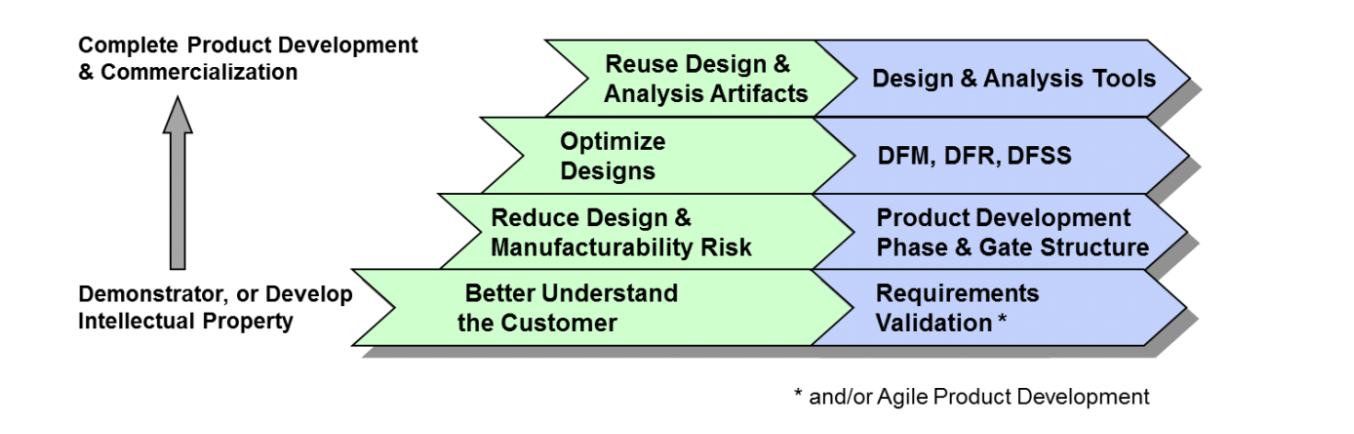

A tailored approach would also consider the type of product development project. A project goal might be to demonstrate a minimum viable product (perhaps a start-up company) or pursue complete product commercialization. The graphic below provides some suggested lean product development objectives and initiatives accordingly.

A lean development process, with the ultimate goal of hardware product commercialization, might place more emphasis on reducing design risk, design optimization & manufacturability.

A lean development process, with the ultimate goal of hardware product commercialization, might place more emphasis on reducing design risk, design optimization & manufacturability.

Should You Invest?

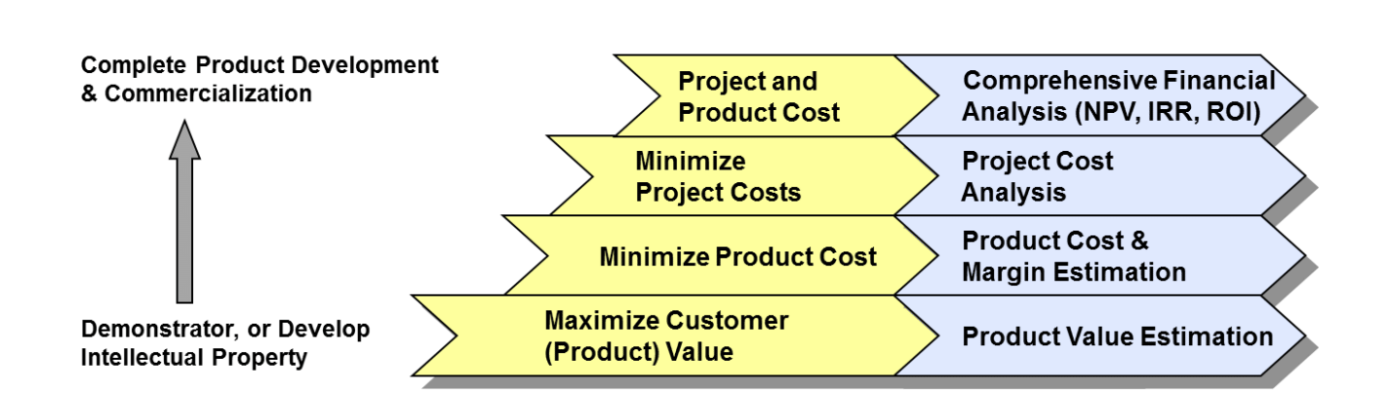

This brings us to our final category of enabling lean: making good business decisions. Investing in a product or project is ultimately a business decision that can be improved with financial estimating and analysis. Here again, we consider the type of hardware product development project and emphasize customer value, product cost and project cost.

A business decision priority for demonstrating a minimum viable product might include (as a minimum) ensuring corresponding value to the customer. Meanwhile, a more comprehensive product or project financial analysis is more appropriate for many (or larger) projects going through complete commercialization.

A business decision priority for demonstrating a minimum viable product might include (as a minimum) ensuring corresponding value to the customer. Meanwhile, a more comprehensive product or project financial analysis is more appropriate for many (or larger) projects going through complete commercialization.

Is Your Product Scalable?

Lean product development approaches are scalable based on several factors; a company may perform some project retrospectives, perform an internal survey or assessment, or begin with some awareness of tools and methodologies.

Do you have too many projects? Projects that weren’t ultimately successful? Resource constraints? High risk of design rework? Sub-optimized designs? Inadequate product margins? Difficult-to-manufacture products? The most effective and beneficial elements of lean enterprise product development could then be down-selected.

Technical Project Management Can Help

For example, a start-up might benefit from a technical project manager who can help facilitate a lean process and focus the team on maximizing customer value. This is a fundamental role and objective applicable to almost any product development effort.

Introduce Lean Production With Our TPMs

We understand that as the number of projects increases and/or the objectives of your product development organization change, your developmental process needs change accordingly. With several projects, you might benefit from many of our electronic hardware development services including project portfolio management, governance process, and team restructuring enabled by a lean-influenced product life cycle process.

There are likely many beneficial opportunities to streamline your product development process, contact us at Product Realization Group for an initial consultation to see how we can help you today.