4. LEVERAGE A LEAN NEW PRODUCT INTRODUCTION PROCESS

By implementing a strong new product introduction (NPI) process, companies are able to reduce time to market, lower costs and scale faster compared to companies who follow a weak NPI process.

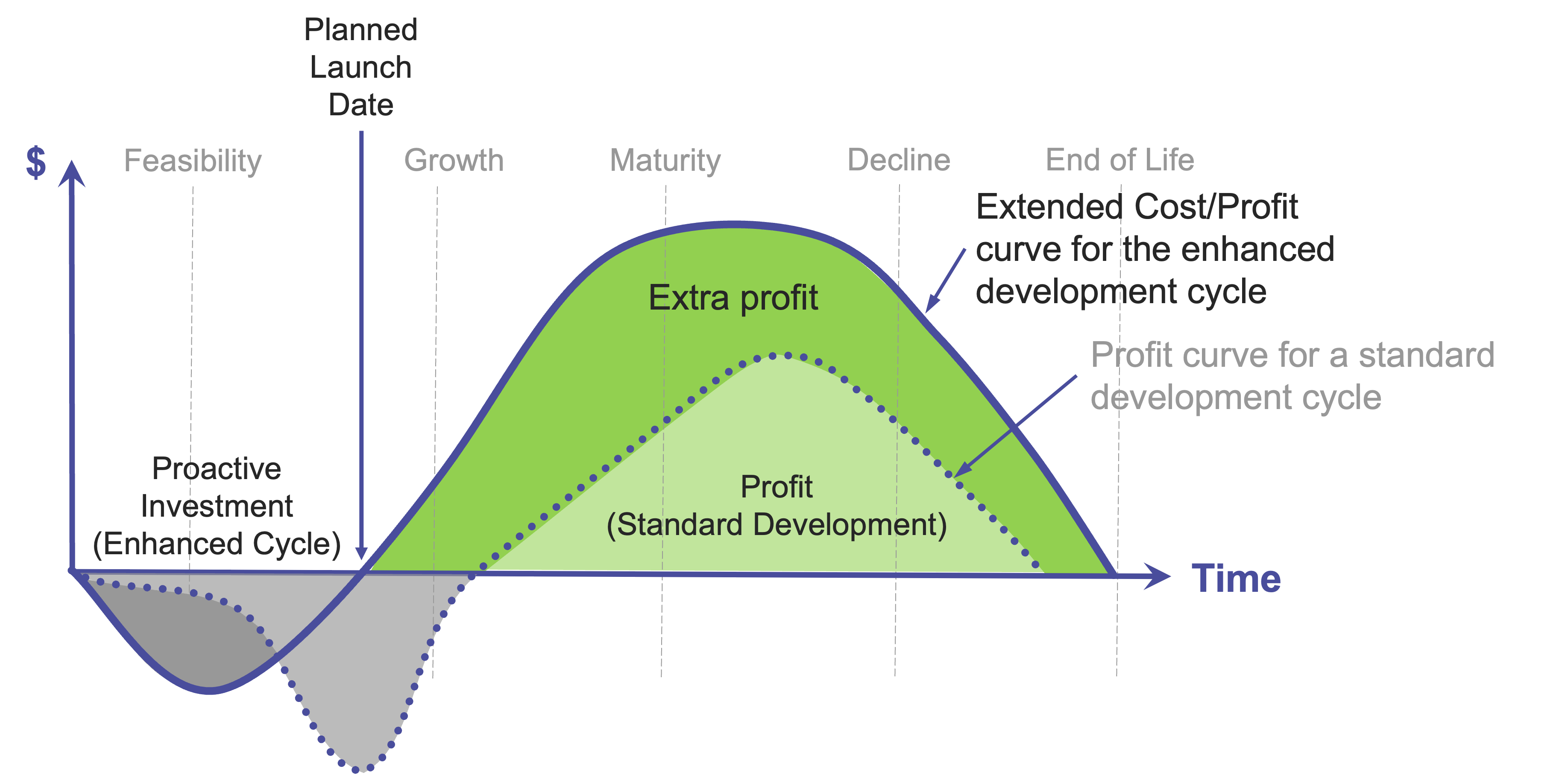

The diagram above contrasts a lack of NPI controls with good NPI process practice resulting in on-time product launch, extra profit, higher top-line revenue and the ability to fund next generation products.

Companies that maintain a strong financial position are more attractive to individual and institutional investors compared to companies that have poor quarter-to-quarter performance. A weak NPI process may result in additional costs such as:

- Unclear or missing product requirements

- Insufficient or the wrong resources

- Teams that are not integrated (no NPI team)

- Incomplete designs

- Not leveraging Design for Excellence (DFX)

- Insufficient test, regulatory and reliability activities

- Risky materials management

- Non-resilient supply chains

- Manual and inefficient processes

- Inadequate tooling and fixturing

- Poor communications (both internal and external)

Let’s take a look at a couple of examples and see what companies can do to ensure success.

Incomplete (or poorly documented) product requirements

Do you suffer from or know someone that has dealt with a poorly written or incomplete product requirements document? If the answer is yes, you’re not alone. For many companies, writing a clear, concise and complete PRD is not a priority and the effect can be catastrophic.

Without a PRD, design and system engineers have no hard requirements to design against, leaving the product specifications up-to interpretation. This can lead to specification creep or simply a lack of focus related to developing products for a specific market segment. Longer term, it becomes more difficult to manage manufacturing, supply chain, reliability, regulatory and customer support with so much variation in the mechanical/electrical/software design and BOMs.

To remedy this problem, successful companies spend the time to write a PRD and document/specify what the initial product needs to do. This ensures everyone is clear on the product requirements (eg. product specifications, features, cost targets, etc.) and is particularly important with hardware products because there are fixed costs associated with building each unit. This seemingly simple task gets everyone on the same page and eliminates ambiguity with respect to the product requirements.

Design for Excellence (DFX)

DFX is more than a buzz-word or something people put on a plaque. It’s a set of services, methodologies or processes that companies integrate to improve their overall business. DFX is particularly important in hardware companies because of the close relationship between Design Engineering and Manufacturing.

More broadly, DFX can include Design for Manufacturing, Design for Cost, Design for Assembly and Design for Testing. In each of these steps, it’s the “Design for” that’s important for a company to move from prototype to production systems. Alternatively, if a product isn’t designed for Manufacturing, there will be assembly issues as the manufacturing team starts to build the first production systems. Finally, if a company doesn’t pay attention to design and parts selection, meeting cost targets becomes impossible.

The same thought process goes for Design for Assembly and Test, where parts must be designed to fit together at scale and sub-assembly and final assembly test requirements are well-defined and documented.

Supply Chain

It seems everyone is affected by Supply Chain issues nowadays.

Beyond the traditional challenges of global Supply Chain management, the pandemic has caused a shortage of some parts and resulted in grid-lock at some major ports, making it difficult to obtain critical parts for your products.

Not paying attention during design activities can create specific Supply Chain challenges. Here are a few examples with some suggestions of what you can do to overcome them.

Custom Parts – the problem with custom parts is they are typically qualified and sourced at one company. To reduce the strain on Supply Chain, companies should qualify a second (or third) vendor, depending on the complexity of a given part. Alternatively, whenever possible, engineering should specify standard parts that are available from multiple resellers and distributors.

Long Lead Times – many companies struggle with long lead times, even for production items, such as computer chips. To deal with this growing problem, companies are placing purchase orders earlier in the product life cycle process, paying a premium for limited stock and taking partial shipments to support production systems.

Supply Chain Resilience – having a robust supply chain is critical for any company that manufactures hardware products. While earthquakes, flooding and building fires are not common, they can wreak havoc on a manufacturing facility and greatly impact the availability of your critical parts. To minimize the impact to your supply chain, sourcing parts from two or three different vendors/companies can reduce the risk of having parts shortages and ensure you have all parts for each production system on-time.

Next week, Mike will discuss how having the right business systems can smooth a product’s journey from prototype to full-scale production.

Mike Freier is Founder and Principal Consultant at the Product Management Consulting Group and has more than a decade in hardware product management/marketing.