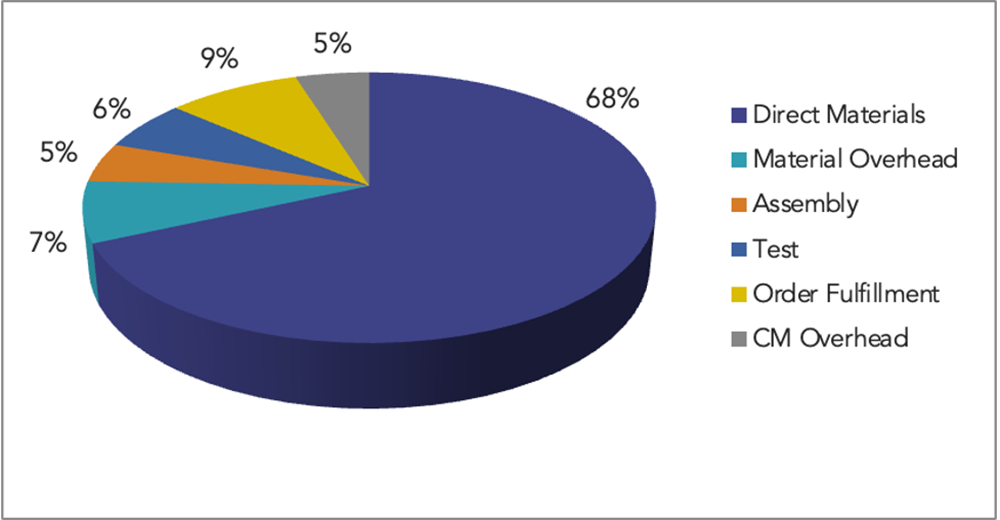

5. DESIGN & PLANNING – Part 2: Planning

Mapping good ideas to product development is best done in the concurrent engineering framework, a collaborative approach to new product introduction. Using the MVP and the product roadmap, you are now ready to move into balancing design concepts with business concerns like costs.

Product Management and Engineering Planning Conversations

Concurrent engineering embraces collaborative planning across multiple teams like product management, hardware and software development, manufacturing and test engineering, and customers.

With enough time and resources, building almost anything is possible, but not necessarily good business. Successful teams meet on a regular basis to talk though customer painpoints. The goal is to understand the difficulty and time required to build and implement a solution.

Hardware requires significant capital to develop and has fixed costs for each unit. So, finding the right balance between faster time-to-market and enhanced customer value is critical to maximizing profit.

Conceptual and Industrial Design (ID)

Once you have a clearly defined MVP, the next step is to work with your engineering team on design concepts. Hold a brainstorming session and try to generate at least 100 designs that capture different components and design methodologies.

Next, based on your Product Requirements document and MVP, identify the top 10 design concepts and why. At your second and third meetings with your team, narrow down the list of possible designs to 3 and eventually arrive at one that best meets your requirements. The final concept is the basis for 3D modeling, detailed design, and analysis as you move into the Development phase.

Don’t forget to consider industrial design issues that impact fabrication and cost:

- Form

- Function

- Human factors

- Ergonomics

For example, if you are designing industrial robots here things to consider.

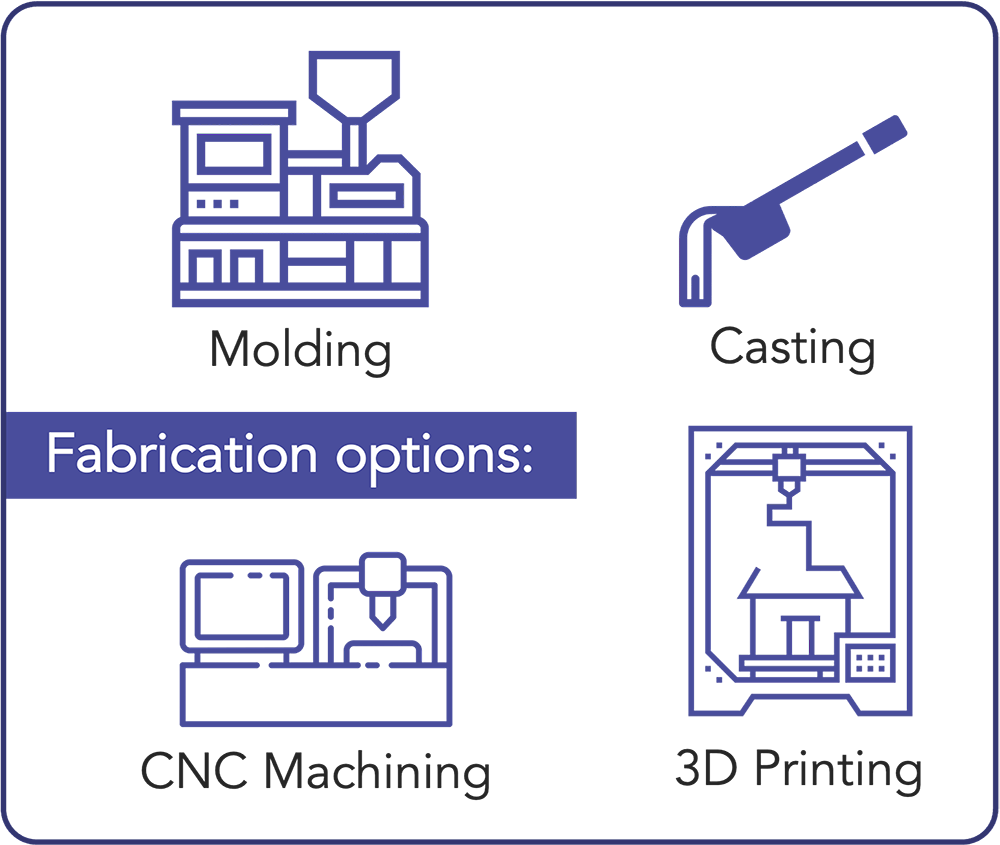

Building on the rough costs estimated in Phase 1, continue to develop and refine your cost model as you get better data on the product and labor costs.

In the example below, direct materials represents 68% of total costs and material overhead, assembly, test, order fulfillment, and contract manufacturing overhead represents 32% or nearly one-third of total costs. Understanding your total product costs is important, because it has a direct impact on your P&L.

Beyond the product costs that are calculated as a percentage of direct materials, there are additional costs to consider.

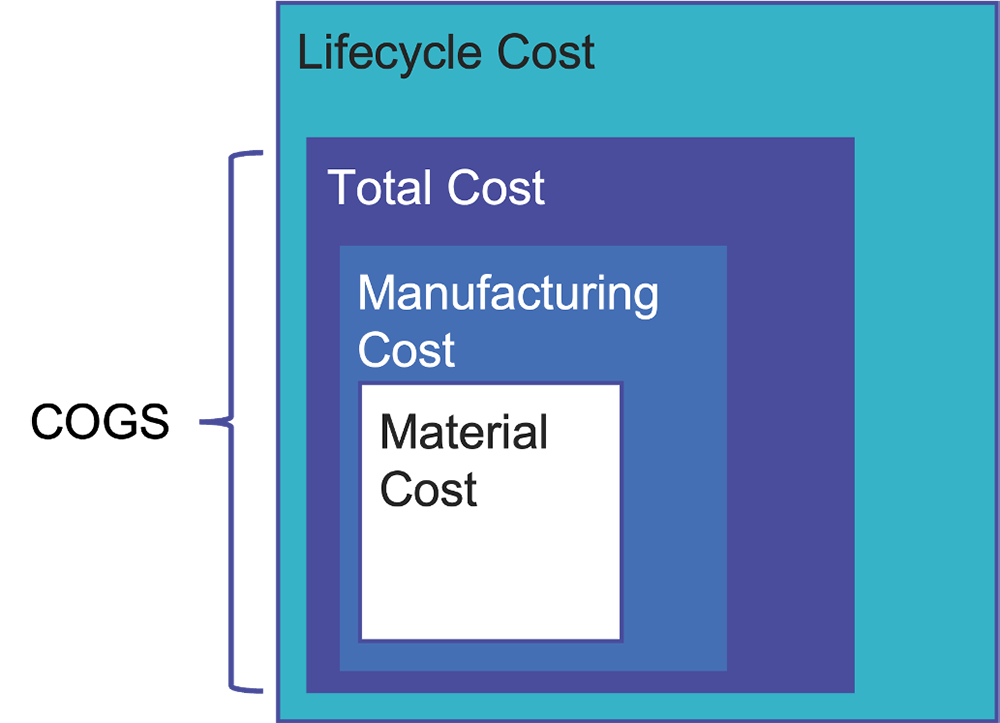

Costs of Goods Sold (COGS)

MANUFACTURING COSTS

- Parts

- Labor

- Manufacturing overhead

TOTAL COSTS

- Marketing, sales, finance, human resources, administration

- Insurance

- Capital equipment

- Other overhead

- Other costs

- Inbound freight

- Product data management

- Purchasing, inventory carrying, cost/markup

- Scrap

- Quality assurance (retest/rework)

- Licenses, royalties

LIFECYCLE COSTS

- Support

- Warranty (repair, replace, recall)

Design and planning go hand-in-hand in the new product introduction process. Getting a handle on your costs, iterating on design, and collaborating using a concurrent engineering framework will set your team up for success.