7. DEVELOPMENT – Part 1: Agile Hardware Development

In the last blog post, we discussed why Design for Excellence (DfX) is important to your business. Building on several important concepts, this blog will focus on the Product Development phase and discuss how incorporating Agile principles can improve and accelerate your hardware product development process.

Engineering Design Specification

To get started, create an Engineering Design Specification (EDS). This is a detailed document that your engineering team creates to align and connect the market and product requirements with more technical specifications. A well written and comprehensive EDS contains all the necessary information to guide the design process and to provide a reference for testing and validating the final product.

Sample Engineering Design Specification Outline for B2B Hardware Products

- Technical specifications

- Functional

- Performance

- Materials

- Validation and verification

- Test plan to confirm product meets all specifications

- Compliance plan for safety and other industry standards

- Safety (UL, CE)

- Others (FCC, FDA, ISO, MIL, RoHS, WEEE and REACH)

- Agency compliance

- Safety (UL, CE)

- Emissions (FCC, CE)

- Product (FDA, ISO)

- Military (MIL)

- Environmental compliance

- Hazardous substances (RoHS)

- Waste (WEEE)

- Chemical substances (REACH)

Concurrent Engineering / New Product Introduction (NPI)

Concurrent engineering, also known as simultaneous engineering, is a method of designing and developing products, in which the different stages run simultaneously, rather than consecutively. It decreases product development time and accelerates time to market, leading to improved productivity and lower costs.

It is also a long term business strategy, with long term benefits to business. Though initial implementation can be challenging, the competitive advantage means it is beneficial in the long term. It removes the need to have multiple design reworks, by creating an environment for designing a product right the first time round.

Concurrent engineering is also a tactic to get the right people aboard the “bus” early, an essential step to ensure your product design is a success. In other words, gain cross-functional alignment by establishing a dedicated working group, or NPI team, at the beginning of the development process.

New product introduction teams should be led by a NPI project or program manager and people from each support function. Below is an example of a typical concurrent engineering team.

Sample Concurrent Engineering Team

- Mechanical Engineering

- Electrical Engineering

- Software Engineering

- Manufacturing/Operations/Quality Systems

- Accounting/Finance

- Field Service/Customer Support

- Operations/Supply Chain/Purchasing

- Product Management

- Sales/Marketing

Or if your company needs a more streamlined team, here are the essential functions to include.

- Engineering Development Team (ME/EE/SW)

- Manufacturing/Operations/Quality Systems

- Service/Support/Other Functions

Each function adds valuable perspectives that ensure your product goes through the product development life cycle, ships to customers, and can be serviced and supported.

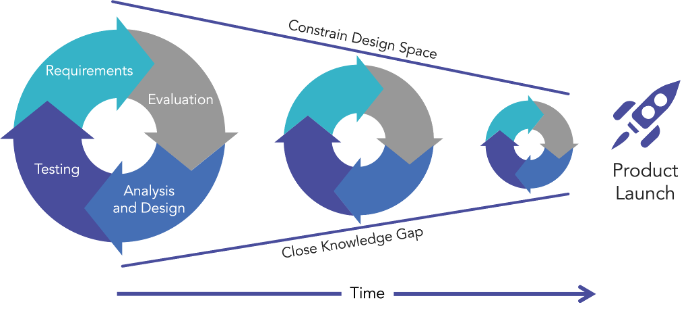

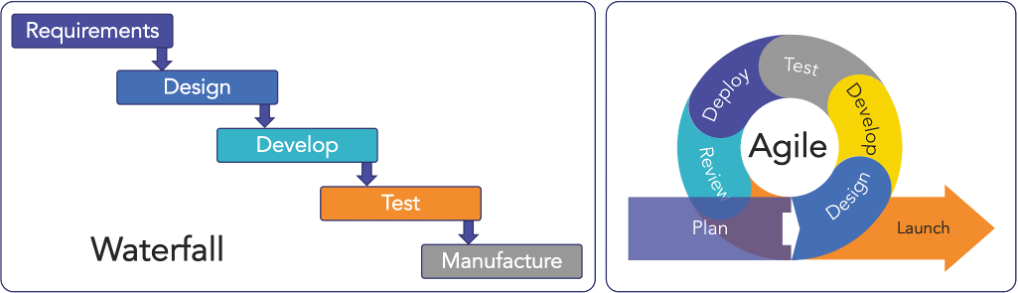

In a traditional (Waterfall) product development processes, design and testing activities are often performed in sequence, with each phase completed before the next one begins. This approach leads to long development cycles and the need for costly and time-consuming rework, if problems are discovered late in the design process.

With concurrent engineering, however, multiple design and analysis activities are performed simultaneously, allowing engineers to identify and resolve potential problems early in the development process. This results in shorter development cycles, better product quality, and a more efficient use of resources.

Agile Product Development

Agile gained popularity in 2001 when the Agile Manifesto was published for software developers. Over time, the concepts and key principles of Agile have been incorporated into hardware product development. Hardware products now get the benefits of Agile, such as shorter lead times, higher quality products, lower costs, and a host of other benefits.

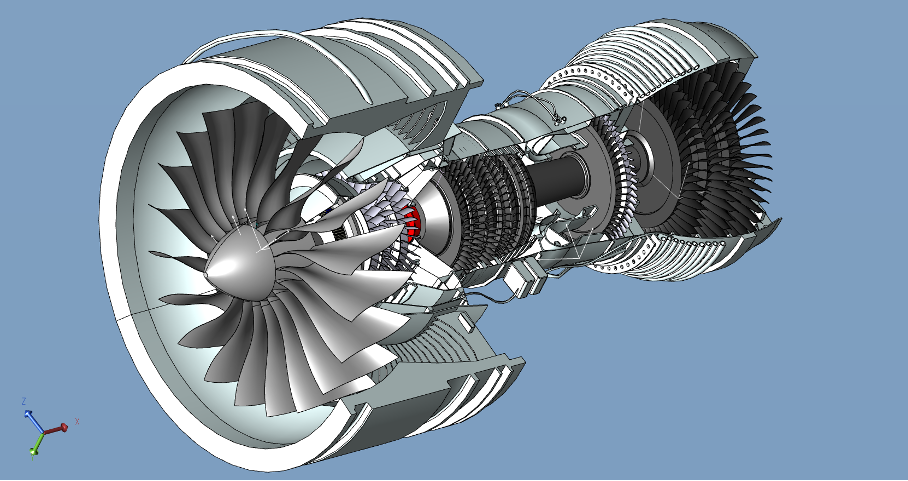

3D CAD Modeling and Simulation

Computer software has come a long way since the early days of 2D computer-aided design (CAD). Mechanical engineers now have the ability to run multiple design scenarios and animated simulations without building a physical prototype. CAD programs can also check clearances for mechanical fit, interference and run a large number of analyses, including stress, strain, fatigue, heat transfer, etc.

The benefit of this technology is that teams can quickly iterate in an Agile design loop and select a final design in a fraction of the time it takes to build a hardware prototype.

Circuit Design and Simulation

Electrical engineers also have the ability to leverage Agile with software created to analyze and optimize circuit design. Not only can these programs lay out pc-boards, but have the ability to analyze AC and DC circuits and a number of related design issues.

- Electrical Design – pc board layout

- Simulation/analysis – verifying circuit design (e.g., power, transients, etc.)

- Manufacturability/DFM – clearances, heat transfer, solder pad size, foot prints, etc.

Rapid Prototyping and 3D Printing

Advances in rapid prototyping have also accelerated product development and enabled hardware teams to embrace Agile. More specifically, 3D printers have become faster, cheaper and capable of producing realistic models that can help engineers and concurrent teams evaluate different scenarios, including ergonomics, ease of assembly, serviceability, etc.

Even though 3D CAD programs are very good these days, handling physical parts can help identify issues and areas for design improvements.

Sub-Assembly and Module Testing

Another way agile techniques can improve your product development process is through sub-assembly or module testing. Analogous to software development, breaking down large tasks into smaller, more manageable pieces reduces the risk that a major or complex issue will be discovered late in the process.

Take robots, for example, you can test a number of components before assembling the fully-functional robot, improving the chance of success, reducing unnecessary rework and accelerating time-to-market.

- PC-board

- Software

- Motor/encoder/bearing assembly (each axis)

- Gripper

- Sensors, camera, and vision

- Cable and connector wiring or pinouts

- Tune PID controller parameters for optimal performance

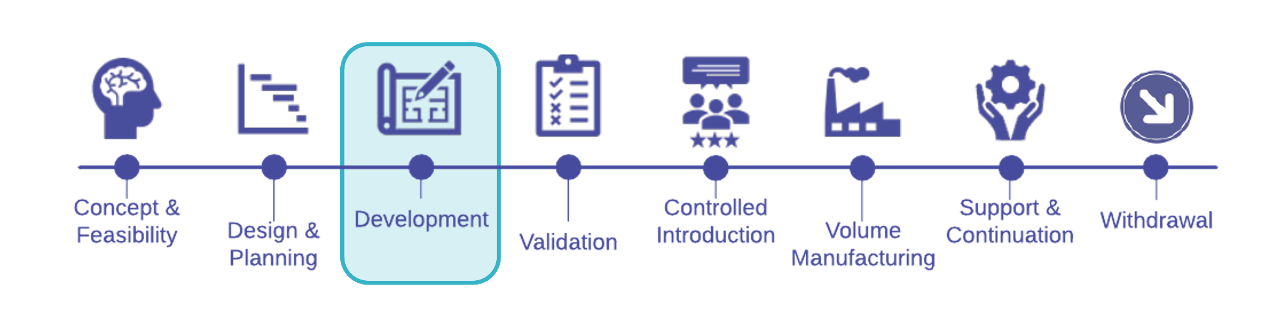

Agile and the NPI Stage Gate Process

Another benefit of an agile approach is its ability to integrate into a traditional NPI stage gate process. This blended model embraces agile, catalyzing teams to get through each development phase faster and work within your established NPI framework.

In summary, Agile is a framework developed for software, but the principles can be applied within hardware development to great success. Using the tools of Agile adapted for hardware – Engineering Design Specifications (EDS), concurrent engineering, modeling and CAD, rapid modeling, and module testing – fits hand-in-glove with the new product introduction process.