A robust supply chain strategy is a crucial aspect of a company’s overall success in today’s dynamic and competitive business environment. A well-designed supply chain strategy enables companies to reliably deliver product, reduce costs, and enhance customer satisfaction. There are key considerations when developing a supply chain strategy, with unique challenges (and opportunities) faced by both emerging and large companies. It’s also important to consider post-purchase considerations that impact the supply chain, such as product returns management, into the overall strategy.

Fundamental Considerations in Supply Chain Strategy Development

Alignment with Business Objectives:

The first and foremost consideration in developing a supply chain strategy is aligning it with the overarching business objectives. The supply chain should be designed to support the company’s strategic goals. This alignment ensures that the supply chain becomes a value-adding component that contributes directly to the organization’s success.

Since businesses run on capital, an essential consideration is the efficient utilization of capital within the context of the supply chain. Managing expenditures on inventory, responsive and resilient operations capabilities, technology, scalability, and protection of Intellectual Property (which was purchased with hard-won capital) are key considerations for the business.

Customer-Centric Approach:

Today, more so than ever before, it is essential for companies to adopt a customer-centric approach in their supply chain strategy. Understanding customer expectations, preferences, and demands is crucial for designing a supply chain that delivers a positive customer experience. This involves factors such as lead time, product availability order accuracy, returns processing, and service levels. Some enterprises, particularly those with disruptive products, may also need to provide an (often overlooked) distinct supply chain for Demo goods to support their business strategy.

Risk Management:

Supply chain disruptions can have significant ramifications on a company’s operations and reputation. An effective supply chain strategy should incorporate robust risk management practices. This includes identifying potential risks, assessing their impact, and implementing mitigation strategies. Companies should resist the temptation to react to risk simply by increasing inventory throughout the supply chain, but instead, strategically manage the type of inventory and pay attention to where it is staged throughout the supply chain. Common risks include geopolitical issues, natural disasters, supplier disruptions, and global economic fluctuations. Ensuring that a supply chain does not have single points of failure is essential in today’s complex global environment. Risk management should absolutely include consideration of Intellectual Property risk as it pertains to decisions about the structure of the supply chain.

Technology Integration:

Leveraging technology is imperative for an efficient and responsive supply chain. Companies should invest in state-of-the-art technologies such as artificial intelligence and data analytics to enhance 24/7 visibility, traceability, and decision-making throughout the supply chain. Technology integration enables real-time monitoring and data-driven insights, facilitating better-informed strategic decisions.

Challenges for Emerging Companies in Supply Chain Strategy Development

Limited Resources:

One of the primary challenges faced by emerging companies is limited resources, both financial and human. Developing and implementing a sophisticated supply chain strategy often requires significant investments in technology, infrastructure, and personnel. As such, emerging companies must carefully allocate their resources to optimize their supply chain operations within budget constraints. Consequently, the choice of ‘multi-functional’ partners with broad, leverageable skills is an extremely important parameter as it pertains to optimizing stretched resources. Further, as capital is a limited resource, it’s essential to design a supply chain that requires limited inventory investment.

Supplier Dependence:

Emerging companies may have a limited pool of suppliers, leading to a higher level of dependence on individual suppliers. This dependency increases vulnerability to disruptions caused by supplier issues such as financial instability, quality concerns, or geopolitical factors. It also increases Intellectual Property risk, unless specific steps are taken to firewall and safeguard critical technologies. Diversifying the supplier base and building strong relationships become critical for mitigating this challenge.

It is highly advantageous to perform a strategic supplier analysis as partners are selected and managed. An emerging firm should attempt to ensure that critical supplier decisions are not simply outsourced to a Contract Manufacturer, since they may not necessarily share their same objectives, and could possibly put the emerging firm in a less advantaged position as it grows and adapts to market changes. These decisions could include strategic inventory placement, supplier diversification (mentioned), and geographic considerations.

Scalability:

Emerging companies may experience rapid growth or fluctuations in demand, making scalability a crucial consideration in supply chain strategy development. The strategy should be flexible enough to accommodate changes in production volume, product variety, and market expansion. Implementing scalable operations solutions that move final assembly onshore as late as possible in the supply chain, such as in various postponement solutions, allows small companies to adapt to evolving business conditions.

Startups also have a key advantage – no legacy operations or supply chain design. Consequently, a startup enterprise can focus all its efforts behind a focused and relevant supply chain, rather than having to deal with legacy operations that may have lost relevance in the tariff, post-Covid, geopolitically charged world.

Case in Point:

Our company engaged with a Silicon Valley startup that started by shipping less than 40 units per month. Initially the company was using generic hardware from original design manufacturers (ODM’s), which required customization at our site. As the company grew, it needed to use more specific hardware which needed software configuration.

Our company provided the client company with a small production area to configure and update software. As the customer grew, the scope of the operation grew to a 2,000 square foot dedicated cell with assembly, test, burn in/stress screening ovens. RMA receiving and test services were added next, as the customer’s needs further expanded. Eventually we expanded the operation to 5 global locations, shipping over 10,000 units per month, prior to their acquisition by a large Fortune 500 enterprise.

Challenges for Large Companies in Supply Chain Strategy Development

Complexity and Coordination:

Large companies often have complex supply chains with numerous interconnected components. Coordinating diverse activities across multiple locations and departments poses a significant challenge. The supply chain strategy must address this complexity by promoting collaboration, communication, and integration among various stakeholders within the organization.

Globalization:

Large companies often operate on a global scale, dealing with diverse markets and regulatory environments. Managing a global supply chain introduces complexities related to multiple suppliers, cultural differences, trade restrictions, and logistical challenges. Developing a supply chain strategy that adapts to these global dynamics is crucial for ensuring seamless operations and compliance with international regulations.

Legacy Systems & Supply Chains:

Established large companies may grapple with legacy systems and supply chains (and supply chain designs) that hinder agility and innovation. Upgrading or replacing these systems to align with modern technologies, circumstances and thinking is a critical consideration in supply chain strategy development. Overcoming the inertia associated with legacy systems allows large companies to embrace cuting-edge solutions for improved efficiency and competitiveness.

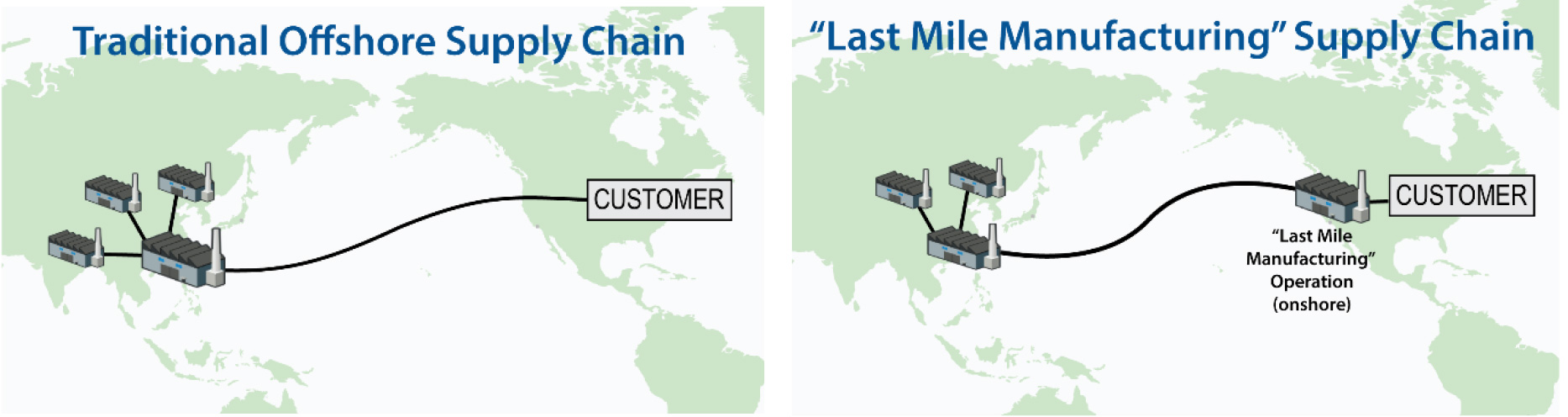

In many cases a realignment may include moving the “last mile” of production to a location that is closer to the customer. This can help reduce costs, improve flexibility, and importantly, protect valuable IP from theft. Approaches like Extron’s Last Mile Manufacturing® can be extremely effective.

Setting and Meeting Sustainability Goals:

Increasingly, larger companies are pledging to adhere to social and environmental standards that support sustainable business goals – environmental management systems, sound labor practices and working conditions, and regulatory compliance. It can be challenging enough to hold first-order suppliers to these goals in many cases, and even more challenging to enforce compliance with lower-order suppliers — the suppliers of these suppliers. In designing supply chain strategies, it therefore is critical to evaluate suppliers early on through this lens, and also to determine the amount of leverage a company will have in holding suppliers at various levels in the supply chain accountable—and what approach will be needed to monitor, train, and manage them.

Case in Point:

Our company engaged with two medium-sized companies that had established operations, already shipping thousands of units. Each was experiencing challenges scaling their operation with their existing providers.

Both customers initially partnered with us as fulfillment customers in our Silicon Valley operation, when experiencing difficulty with their local providers that had only limited services and local scale. Our flexible, scalable services model allowed both medium-sized companies to expand more effectively and efficiently to global scale, with one becoming a major customer in our EU facility. The other is working with us to stand up a dedicated facility in the UK. Both customers were able to leverage our company’s global capabilities, which included customs documentation, exports, imports, and more. This allowed each to scale to dozens of dedicated staff and 50,000+ sq ft engagements in multiple continents.

Integration of Product Returns in the Supply Chain Strategy

Importance of Product Returns Management:

Product returns and responsive replacement of defective products are an inevitable aspect of modern commerce, and effective management is crucial for maintaining customer satisfaction and minimizing financial losses. While it’s often overlooked, especially by small companies, a comprehensive supply chain strategy should include a dedicated plan for handling product returns, encompassing design for serviceability/repair (DFX), reverse logistics, refurbishment, recycling, and customer communication. Failure to do this can mean that all the goodwill generated by a robust supply chain strategy can be eroded by a failure to design a similarly robust post-purchase strategy.

Reverse Logistics Optimization:

Efficient reverse logistics is essential for managing product returns effectively. This involves the seamless movement of products from the customer back to the manufacturer or another appropriate destination, such as an outsourced solution provider that specializes in Returns Management. The supply chain strategy should incorporate streamlined processes for handling returned products, including assessment for restocking, refurbishment, or disposal. The strategy should also include information systems that provide 24/7 visibility into each element of the reverse logistics supply chain.

Customer Communication and Experience:

Clear and transparent communication with customers regarding return policies and procedures is vital for a positive customer experience. A supply chain strategy should include mechanisms for providing customers with easy-to-understand return instructions, tracking capabilities, and timely resolution of return-related inquiries. Positive experiences during returns can enhance customer loyalty.

Data Analytics for Returns Management:

Utilizing data analytics is critical for understanding the reasons behind product returns and identifying patterns. By analyzing return data, companies can gain insights into product quality issues, customer preferences, and potential areas for improvement in the supply chain. This information is valuable for refining the overall supply chain strategy and reducing the incidence of returns. When outsourcing returns management elements, it’s important to select a solution provider that can help capture highly detailed information in these areas.

Summary

Developing an effective supply chain strategy is a multifaceted process that requires careful consideration of various factors. For emerging companies, challenges related to limited resources, supplier dependence, and scalability must be addressed with strategic resource allocation and flexibility. Large companies, on the other hand, grapple with complexity, globalization, and legacy systems, necessitating coordinated efforts, global adaptation, and technology upgrades.

Moreover, the integration of product returns management into the supply chain strategy is crucial for maintaining customer satisfaction and operational efficiency. By optimizing reverse logistics, enhancing

customer communication, and leveraging data analytics, companies can turn product returns into an opportunity for improvement and customer retention.

Ultimately, a well-crafted supply chain strategy aligns with the broader business objectives, incorporates a customer-centric approach, manages risks efficiently, leverages technology, and adapts to the unique challenges faced by companies of different sizes. In the ever-evolving business landscape, a dynamic and responsive supply chain strategy is a key driver of sustainable success.

Sandeep Duggal is the CEO of Extron Inc. For over 25 years, Extron has provided its clients with supply chain solutions designed to improve flexibility, reduce cost, and reduce risk. Extron specializes in the emerging field of Last Mile Manufacturing®, providing last-mile product assembly and integration, order fulfillment solutions, returns-management solutions, and demo-loaner solutions. Prior to joining Extron, Sandeep held various operations and materials management positions at Sun Microsystems, Inc. He also worked in marketing at Intel Corp in Hillsboro, OR and as a strategy consultant at Monitor Company in Cambridge, MA. Mr. Duggal is an accomplished public speaker, frequently speaking on topics associated with various aspects of Last Mile Manufacturing. He has also served as a guest lecturer at Stanford University. Sandeep holds a BSE (cum laude) in Mechanical Engineering from the University of Michigan, Ann Arbor, an MSE in Industrial Engineering/Engineering Management from Stanford University, and an MBA (with distinction) from The Harvard Business School, Harvard University.