3. RESOURCE MANAGEMENT

Last week Mike talked about how to develop your products more competitively in a downturn. This week, he looks at your resources/people and discusses ways to make effective decisions about what to keep close (in-house) or sub-contract (outsource).

People are key to any successful business – getting the right people “on the bus” to focus on core competencies, as well as, leveraging outside support for non-core competencies, can help reduce your burn rate and give you a better chance for survival.

Understand what functions are critical (core) for your business and which are not. Depending on your business situation, these may vary. Some functions to consider include:

- Marketing/Sales

- Product Management

- Engineering Development

- Legal/Contracts

- Supply Chain/Manufacturing

- Quality/Reliability

- Finance

- Distribution/Fulfillment

- Customer Support/Field Service

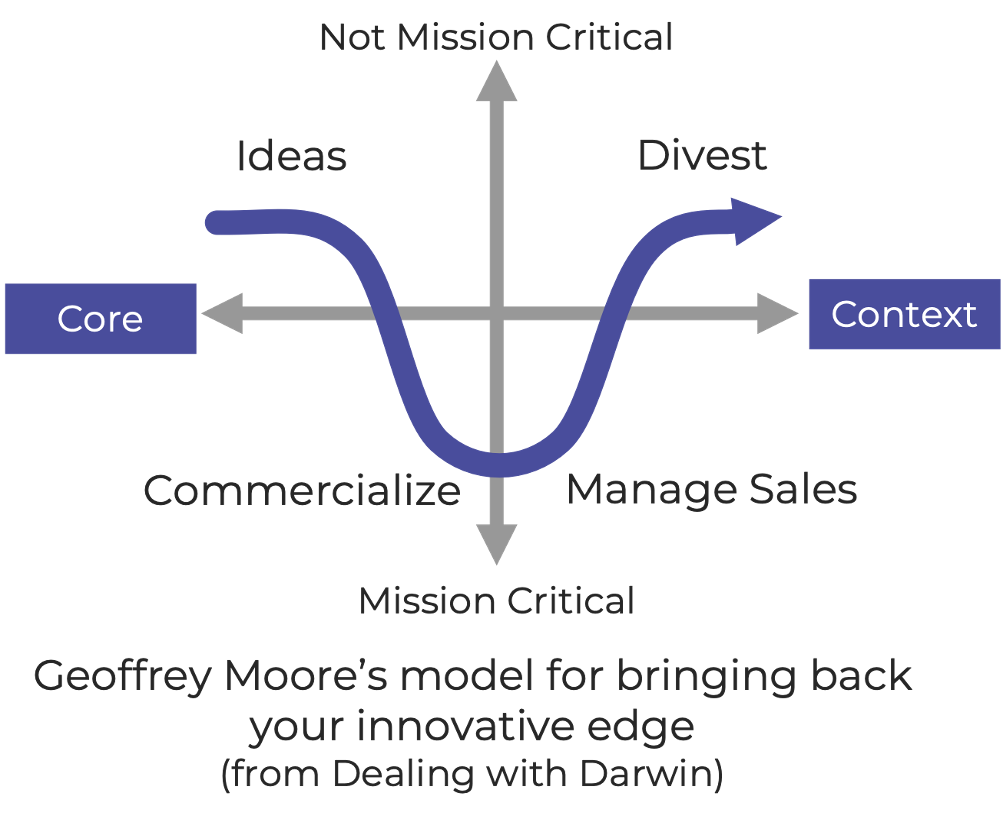

For example, if your core competency is software development, then you would want to outsource as much of the non-software related activities (“Context” in the diagram above: e.g. hardware development, regulatory, manufacturing, etc.) and focus your internal resources on software development.

Where possible, leverage partners engaged in the product development process, such as distributors, manufacturers, fabrication companies, etc. to provide insights as part of their value proposition. For example, ask your electronics distributor to identify obsolete parts, sole source components and long-lead time items before you finalize your design.

Leveraging Development and Manufacturing Partners

One unfortunate side effect of a down cycle, is companies often need to trim their headcount to survive, which can include engineering resources. To offset this gap, companies can reach out to strategic partners that have similar or complementary skills and resources to their core engineering team. Let’s take a closer look at a couple of examples.

Design Engineering – ME/EE/SW (development)

Outsource work to a reputable mechanical, electrical or software engineering firm to free up resources to work on your core business.

Contract Manufacturers

Move non-critical or legacy products to a Contract Manufacturer (CM). By design, CM’s are set up to provide flexible, low cost manufacturing services and are able to share overhead and fixed costs across their entire customer base.

If you are feeling a need to reduce your headcount then act early and make sure you truly understand which people are core to your business and those are non-critical and can be outsourced. Many companies cut resources without having backup resources available, and while this gives a short-term improvement to their bottom line, it causes the recovery to be much slower when things get better (and they will).

A big factor in recovery is the long-lead time to source, recruit and on-board key staff, all over again, thus delaying their ability to grow when the economy recovers.

Note: If you would like more information about recommendations for reputable partners that PRG has worked with, please contact us directly.

Next week, Mike will show how using a strong New Product Introduction Process can speed your product to market and profit.

Mike Freier is Founder and Principal Consultant at the Product Management Consulting Group and has more than a decade in hardware product management/marketing.