5 Surprising Facts I Learned when I Visited Local Manufacturing in India

Insights from the field by Shirish Joshi, PRG’s Manufacturing Operations and Supply Chain expert

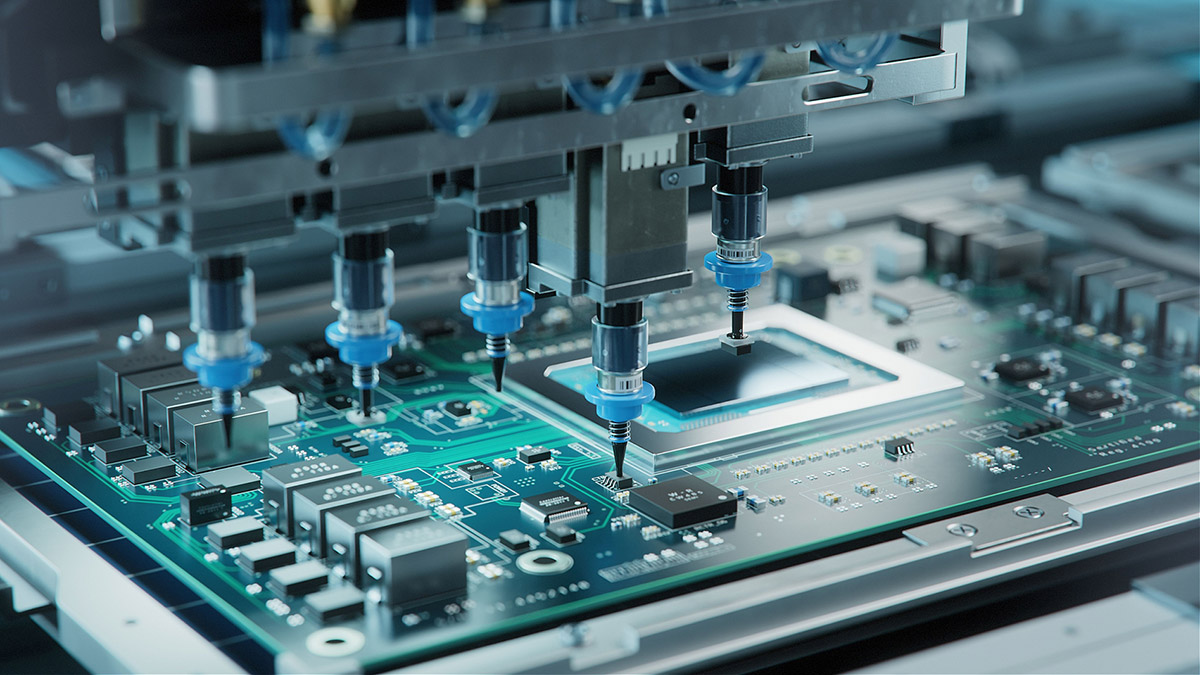

I recently visited India to inspect some of the smaller electronic manufacturing services (EMS) also known as contract manufacturing companies CM’s to understand their capabilities for manufacturing for US companies.

Whilst the “Big 5” EMS (think Foxconn or Flex) already have a well-known presence in India, there are several smaller EMS providers with good capabilities, and these mostly seem to be clustered around the cities of Chennai, Bangalore/Mysore, New Delhi’s suburbs, and Poona, alongside the major players. It’s well-known that some major US and European companies have been moving some or all of their production to the bigger EMS in India (Apple, Logitech, Bosch and Iskra Telcom, to name a few). Still, these smaller EMS could be very useful to US companies looking to move production from China.

I focused on five smaller companies in the Bangalore/Mysore region. All are eager to grow their USA customer base; some already have a presence in the USA to provide local support.

Five key facts about regional EMS in India

- While these companies are classified as Tier 3 or 4 within the EMS ecosystem, with annual revenues in the $25M-$300M range, they all have well-established PCBA and box-build facilities.

- Their number of PCBA lines varies from 3-10, and they all have several box-build cells.

- Most can offer additional design services for hardware, firmware, and software, but all five have clients from Europe, Japan, and the USA.

- They focus on the defense, automotive, aerospace, and medical industry sectors but also do some work in the IoT and Consumer spaces.

- Several smaller companies have facilities within Export Zones, meaning they do not pay excise duty for inbound components and sub-assemblies.

According to their data, customers shifting assembly to India are still obtaining pieces of the product from China due to cost. Items such as the bare PCB, plastic moldings, etc., are hard to source for lower costs outside China.

It is worth investigating these smaller players to diversify your manufacturing base and take advantage of the capabilities of India.

If you want to learn more, contact Product Realization Group for a free consultation.