Wayne Miller

New Product Development and Introduction

Many companies, especially for high-complexity products such as energy storage and robotics, are moving away from outsourced manufacturing to establish their own internal operations. In fact, Kearney’s 10th Annual Reshoring Index finds that reshoring has substantially increased during the past decade.

This paradigm shift, driven by the need for closer design and production integration, poses opportunities and challenges. This article delves into the essential steps and considerations to set up an effective internal manufacturing facility tailored for the hardware-based product industry.

Background:

For emerging technologies it is common to employ an iterative development process to go from product concept to production release. Frequently, new concepts draw upon technical distinctions for novel applications using established technologies. This trend is evident in various sectors such as using robotics in last-mile delivery, autonomous vehicles, and agriculture. While many of these products utilize similar electronics, sensors, and motors, intricate robotic systems pose distinct challenges and integration requirements for diverse applications. The demonstration of the business use case and essential MVP (minimum viable product) features is pivotal in garnering investment, assembling a team, and establishing the viability of the company.

Complex systems require several technical disciplines to develop, and growing teams build expertise over time. So, products continue to evolve over time as the team grows and learns. The dynamic relationship between early product concepts and future iterations is the foundation of agile hardware development.

Building complex products

These systems often have large bill of materials (BOMs) with high component costs. It is not practical to build large quantities of early prototypes during the early stages of development, especially in challenging funding environments. The tendency is to reuse critical components even if they evolve over time and update them as necessary, making maintaining product configurations more challenging. This is compounded when software compatibility is added to the equation.

First, technical expertise, component reuse, and rapid iteration make handing off product assembly or manufacturing to an outside party challenging. Second, close proximity between design and production teams also enables faster prototyping, testing, and new idea implementation, leading to shorter product development cycles. Finally, integrating research and development (R&D) with manufacturing facilities also fosters innovation.

On the contract manufacturing (CM) side, most of the larger CMs expect products to deliver a solid return on investment (ROI) with minimum risk as a result of consolidation in the contract manufacturing (CM) space. For example, a major CM recently said they would not consider building a product with less than $10M annual manufacturing revenue — a high bar for a product prior to market validation or acceptance.

In this environment, many companies have learned that it is easier to build products internally.

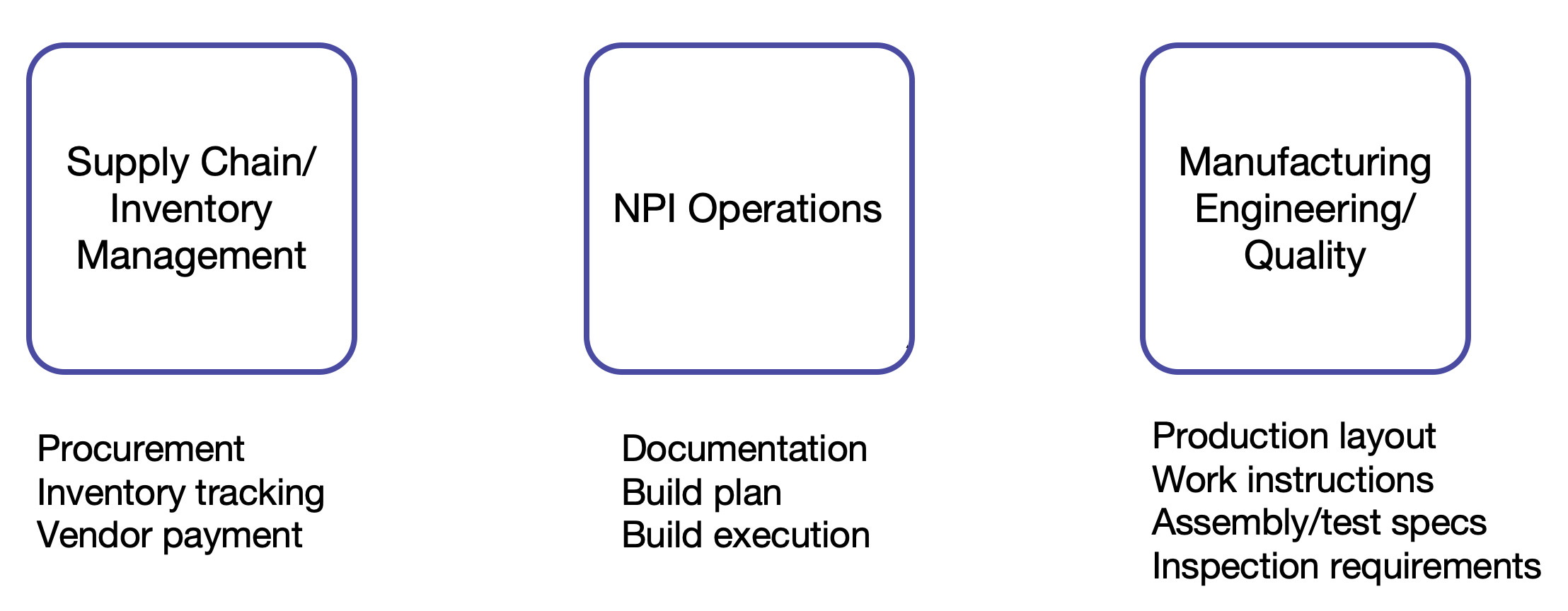

Operations Team

Early product builds are generally performed by engineering teams with technician support in the lab. As the product evolves and demand increases, adding dedicated resources to support product builds helps the product design stay on track. Operations resources include procurement and tracking of materials, organizing and schedule builds, and manufacturing engineering. Of course, this is dependent on the type of product and build quantity requirements. For a product with high complexity, low volume and minimal tooling, the primary functional areas to support internal manufacturing are listed below.

Facility

One of the most fundamental aspects of setting up an internal production operation is defining the facility space. The area required depends on many factors, but the most critical will be for inventory storage (warehouse) and production build stations. If there are multiple products it can be advantageous to have separate lines for each depending on material and process commonality. If there is limited space for only one line, designing the line to easily move material in and out of the production line will be important.

Inventory management

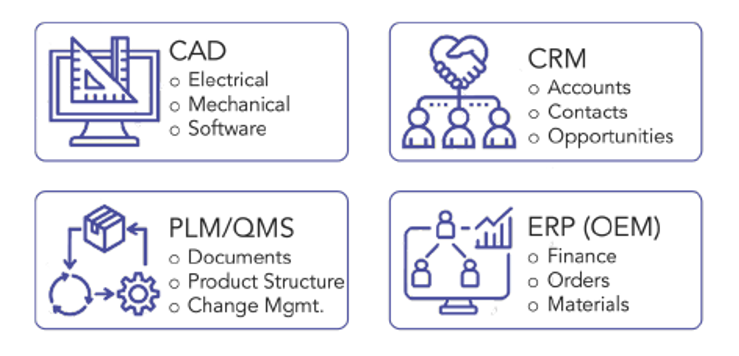

Organizing inventory is critical for productivity. If people spend too much time searching for parts they are not producing anything. Of course, there are several approaches for this but a common method is organizing by commodity. In this case electronics components with similar size and environment requirements (e.g. temperature, static electricity sensitivity) should be considered. Incorporating an effective labeling scheme that includes part numbering and inventory location is a critical function. Having separate storage for electronic components, mechanical components, printed circuit board assemblies (PCBA’s) and commercial off the shelf items (COTS) is generally a good approach. Security for high value components is also recommended. Larger parts and assemblies that are palletized may need to be stored in multiple ways, such as on pallets in their original packaging and broken down in bins to be brought in and out of the production build area. Most financial and production planning systems (ERP/MRP) have the ability to purchase and track materials by part number and inventory location. If these systems are available, it can save time and better track valuable components.

See example below of how business systems can be used to better manage to data flow from customer relationships through materials planning:

Production Line

Designing the production line depends on factors such as product size, build team size and the product assembly strategy. For complex low volume products there are relatively fewer operators and lower throughput (build speed) requirements. Therefore, it wouldn’t be necessary to create a large quantity of workstations to build the product. In this case it could be effective to create work cells that can accommodate several operations. It can be effective to set up flexible cells where material can be rolled in and out to the build area and potentially be assembled on moving carts. In this case the material and tools are fixed and the product can be moved between stations.

Designing the production line depends on the types of operations and tooling that is required, such as test equipment, special tools, and fixturing. It is also helpful to consider how the work instructions or other assembly documentation will be accessed. This may require a computer workstation and monitor to access the information. Keeping materials and tools required, assembly order of operations and any special instructions.

There are Manufacturing Execution Systems (MES) available which can help structure this information and processes. A Manufacturing Execution System is a computerized system used in manufacturing to track and document the transformation of raw materials to finished goods. An MES provides information that helps manufacturing decision-makers understand how current conditions on the plant floor can be optimized to improve production output. An MES works as a real-time monitoring system to enable the control of multiple elements of the production process (e.g., inputs, personnel, machines, and support services). These systems also help track assembly and quality inspection steps, traceability and serialization for complex builds.

NPI Operations

Accurate product and manufacturing documentation are critical for successful production builds. Change management is a critical step in early stages to ensure products have the correct materials and revision. Product Lifecycle Management (PLM) systems play a crucial role in improving and optimizing production processes. The benefits of implementing PLM systems in production are multifaceted and contribute to increased efficiency, better collaboration, and enhanced product quality.

PLM systems automate change management processes, making it easier to evaluate, approve, and implement changes to product designs or production processes. This efficiency in change management contributes to faster response times to market changes or customer feedback.

Product Cost

Shifting from engineering development into volume production results in a corresponding shift in the elements that make up product cost. The cost for making a few units in the prototype phase may vary dramatically and be much larger than the cost for making these same units in volume production.

Summary

Establishing an internal production facility can be a critical part of a successful startup. There are many considerations which will contribute to successful product builds, cost management and operational efficiency. The Product Realization Group has decades of experience building products at internal and external factories. We can help your company determine the manufacturing strategy, systems and processes, and production execution. Please reach out to [email protected] for a complimentary consultation.

If you enjoyed this article, you might also want to check out these blogs.

Meet Wayne Miller, New Product Development And Introduction

Finding The Right Manufacturer And Tackling Tooling Challenges