Expert Insights on Defining Requirements and Quality in Hardware

Scott Weinstein, Quality & Reliability, Principal Consultant at Product Realization Group

Scott Weinstein is a hardware development and manufacturing veteran with 25+ years of experience leading quality and reliability engineering programs at global companies, including Roku, Ford, Whirlpool, Keurig, Sonos, Harman, and Johnson Controls. A quality leader, Scott specializes in product design and operations for high-tech hardware companies. Scott has an MBA from the Worcester Polytechnic Institute and a Bachelor in Electrical Engineering from the Georgia Institute of Technology.

In today’s competitive world, quality is not just a buzzword, it’s a critical factor for survival. That’s why Scott Weinstein, a seasoned expert in product design and operations, is here to share his insights on the essential principles of quality and reliability. His four-part series on Requirements and Quality is a must-read for anyone who wants to stay ahead of the curve. In the first part, gain valuable insights on how requirements and quality go hand in hand to create an unparalleled customer experience. Don’t miss out on this opportunity to learn from the best and take your business to new heights.

A conversation about quality begins with requirements that define the features, design, and performance that delivers value to the customer. Read on to learn more.

Why should we care about requirements?

I’ve seen this so often in a wide variety of organizations, engineering teams developing a new product without any requirements. It is astonishing to consider that anyone could think they could effectively design and manufacture a new product without first establishing a clear definition of what that product should be.

Now, I’m not talking about innovation, that is done with few constraints. However, New Product Development (NPD) or New Product Introduction (NPI) should have clear objectives for what the product should be, which can then be used to drive engineering and manufacturing requirements. These requirements can include things like key features, what the product should look like, how it should perform, where it will be used, and how long it should last. Having requirements early in the development process can provide a number of benefits.

Firstly, the design team members are all working to the same plan. And the larger the design team, the more important this becomes. Especially if the design team members are not all in the same geographical location. This team could include electrical engineers, mechanical engineers, software engineers, system engineers, safety engineers, quality engineers, and reliability engineers.

And then, when it becomes necessary to change a requirement during the development cycle, this happens more often than not; we can have a process to determine the associated impact of the change if the change should be made, and then inform all the impacted parties of the change. This change control process can evaluate the impact on development & product cost, product quality, and the development schedule.

Most importantly, having clear requirements greatly lessens the number of redesign cycles required during development and, in turn, reduces the resources and cost of development and shortens the time to market for the new product.

One of my favorite metrics or Key Performance Indicators (KPIs) for New Product Development is First Pass Design Success. That’s basically the percentage of products developed meeting all requirements without additional development cycles. With a focused continuous improvement effort on the development process, I’ve seen this KPI improve from under 50% to well over 80% in less than one year.

Finally, these requirements are needed to determine when your product is complete. In other words, when your product meets all the product requirements. Otherwise, without requirements, it would be hard to tell when you’ve successfully completed development.

How does quality relate to requirements?

Let’s start with the definition of Quality. There are many definitions, but here are a few of my favorites. And yes, I have favorites; that’s how you know I’m a quality guy.

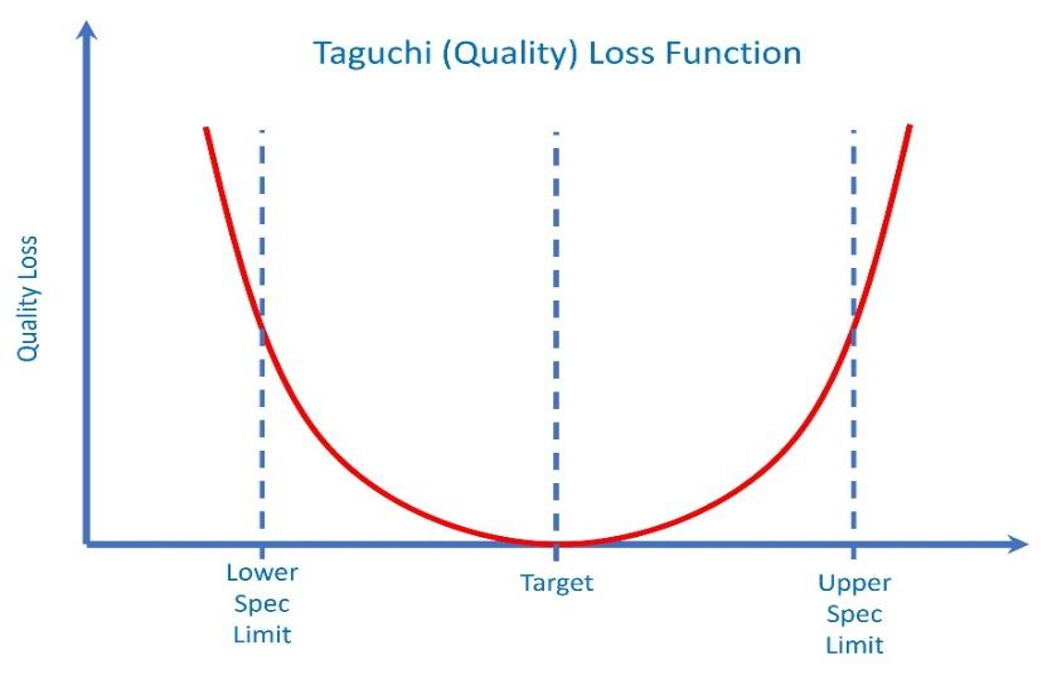

- First, minimal variation around the target. This could be referred to as Six-Sigma, zero defects, or even the Taguchi Loss Function.

- Next, meeting or exceeding customer needs and expectations. This one is probably used most frequently.

- And finally, simply, conformance to requirements.

And what do these definitions have in common? That’s right, targets, expectations, and requirements. Without documenting our product’s targets, expectations, and requirements, we will have a very hard time determining the quality of these products. And as a quality guy, I need to do this during New Product Introduction and in Mass Production.

These requirements can take the form of user stories, functional requirements, non-functional requirements, performance requirements, quantitative requirements, etc., But ultimately, you should be able to determine conformance to those requirements.

Why do quantitative requirements matter?

I tend to lean toward quantitative requirements as much as possible. This facilitates the first definition of quality I provided. Minimal variation around the target. So quantitative requirements ideally have a target and tolerance, like 45 +/- 5, or can just have upper and lower specification limits, like 40 to 50. With quantitative requirements, we have the ability to use statistics to measure such things as capability and stability and then use that information to predict future performance.

Take the Taguchi Loss Function, which is a way to calculate and quantify the cost of deviations away from a target value in product quality. So we are not just verifying a binary requirement, good or not good, but we are measuring “goodness” with the measurement of a variable.

Attempting to assess the quality of a new product without the necessary requirements is akin to driving to a new location without a map. Although you may have a general idea of the directions and may ultimately reach your destination, it will be a faster, less expensive, and easier journey if you use a map. Please join us next week for an in-depth analysis of how requirements should be defined for the best business outcomes.

Are you curious how to improve your hardware product’s quality and reliability? Contact us for a free consultation today. Or read on and learn more about Agile hardware development from the experts at Product Realization Group.