6. SUMMARY

In our combined 120+ years of experience we’ve seen downturn cycles repeat several times and, each time, we’ve helped companies to take a pragmatic approach to managing the situation they find themselves in during a recession.

In the past we’ve noticed that certain practices provide a basis for good business management in lower or negative growth environments and these fall into four groups that were covered in this blog:

- Product Realization

- Resource Management

- New Product Introduction

- Business Systems

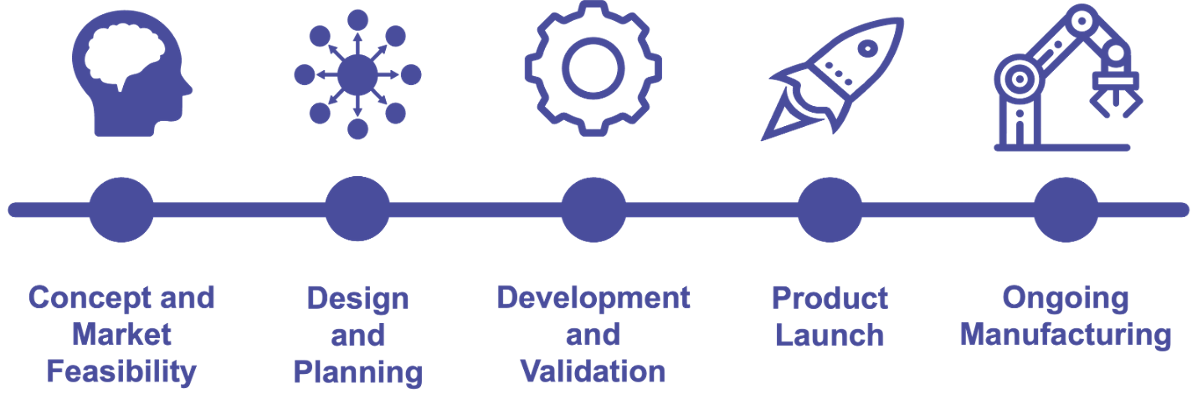

Product Realization – see the whole blog here

The first step is to define your product development strategy to align with your core business competencies (e.g. hire internal resources for core business and outsource non-critical tasks or projects). Second, structure your development to support your unique product profile (e.g. target markets, level of complexity, volumes, cost targets, etc.).

Every company knows the general order that things need to be done in, but not all are able to make the hard decisions around this optimized strategy to adopt in times of stress or threats to business profitability. As a result, they wait too long to make the changes that will build towards future success.

When thinking about your strategy there are several product realization and commercialization options to consider from a perspective of managing for success:

- Product development – In-house vs. outside

- Designing in standard vs. custom components

- Manufacturing – In-house vs. outside

- Original Design and Manufacture (ODM)

- Joint Development and Manufacture (JDM)

- Last Mile Supply Chain

Companies that implement an optimized strategy early in the product life cycle can outperform companies with a weak product realization process and increase the chances of surviving a downturn.

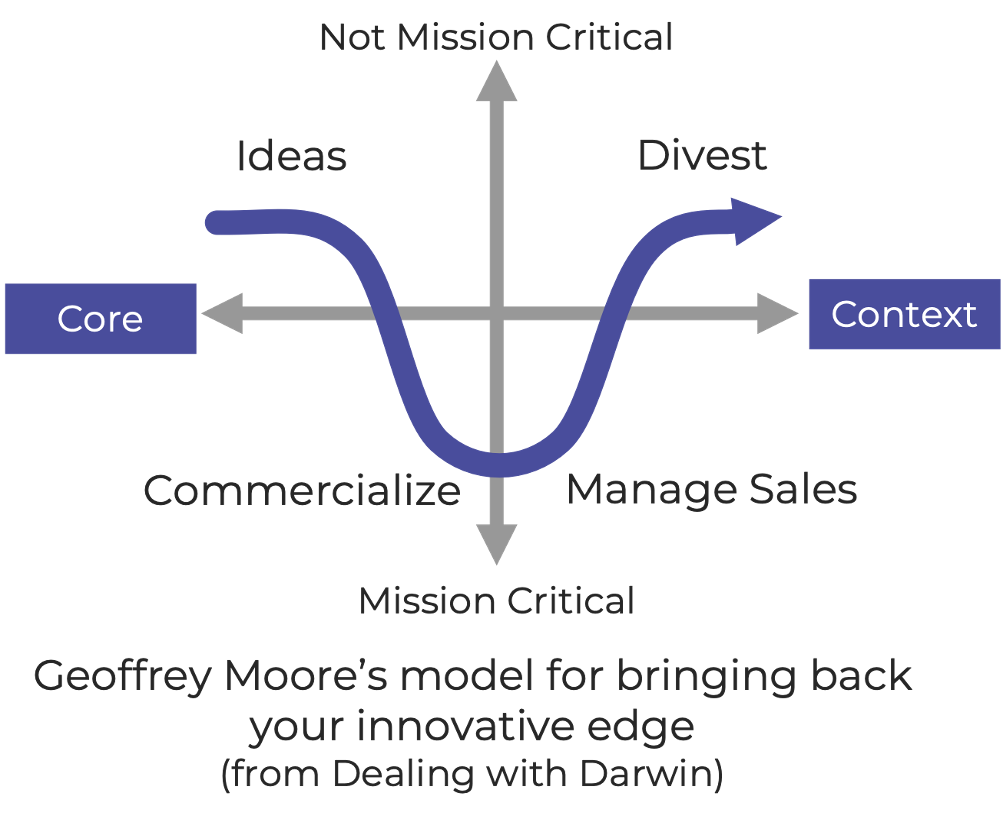

Resource Management – see the whole blog here

People are key to any successful business – getting the right people “on the bus” to focus on core competencies, as well as, leveraging outside support for non-core competencies, can help reduce your burn rate and give you a better chance for survival.

Understand what functions are critical (core) for your business and which are not. Depending on your business situation, these may vary. Some functions to consider include:

- Marketing/Sales

- Product Management

- Engineering Development

- Legal/Contracts

- Supply Chain/Manufacturing

- Quality/Reliability

- Finance

- Distribution/Fulfillment

- Customer Support/Field Service

For example, if your core competency is software development, then you would want to outsource as much of the non-software related activities (“Context” in the diagram above: e.g. hardware development, regulatory, manufacturing, etc.) and focus your internal resources on software development.

Where possible, leverage partners engaged in the product development process, such as distributors, manufacturers, fabrication companies, etc. to provide insights as part of their value proposition. For example, ask your electronics distributor to identify obsolete parts, sole source components and long-lead time items before you finalize your design.

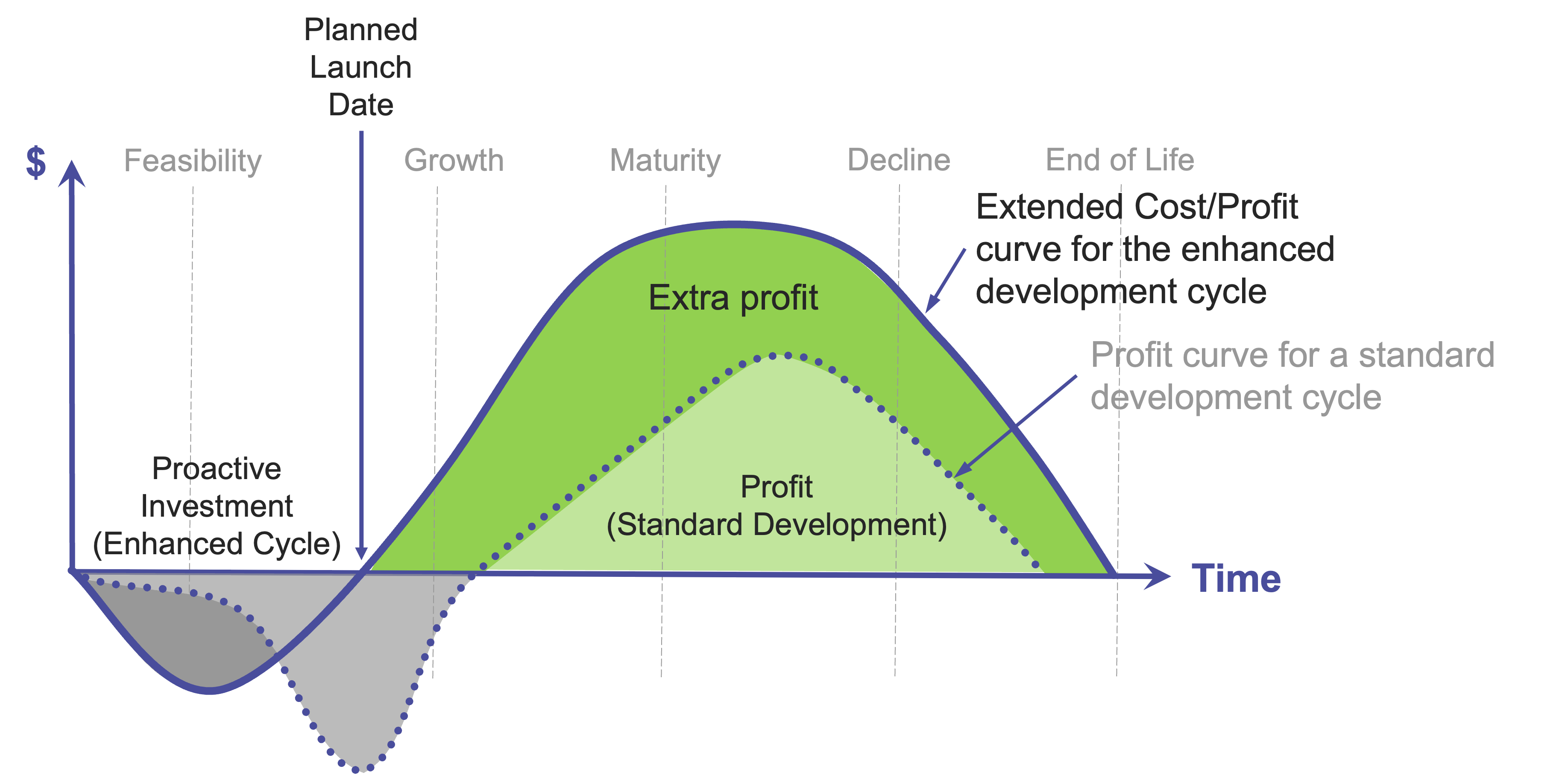

New Product Introduction – see the whole blog here

By implementing a strong new product introduction (NPI) process, companies can reduce time to market, lower costs and scale faster compared to companies who follow a weak NPI process.

The diagram above contrasts a lack of NPI controls with good NPI process practice resulting in on-time product launch, extra profit, higher top-line revenue and the ability to fund next generation products.

Companies that maintain a strong financial position are more attractive to individual and institutional investors compared to companies that have poor quarter-to-quarter performance. A weak NPI process may result in additional costs such as:

- Unclear or missing product requirements

- Insufficient or the wrong resources

- Teams that are not integrated (no NPI team)

- Incomplete designs

- Not leveraging Design for Excellence (DFX)

- Insufficient test, regulatory and reliability activities

- Risky materials management

- Non-resilient supply chains

- Manual and inefficient processes

- Inadequate tooling and fixturing

- Poor communications (both internal and external)

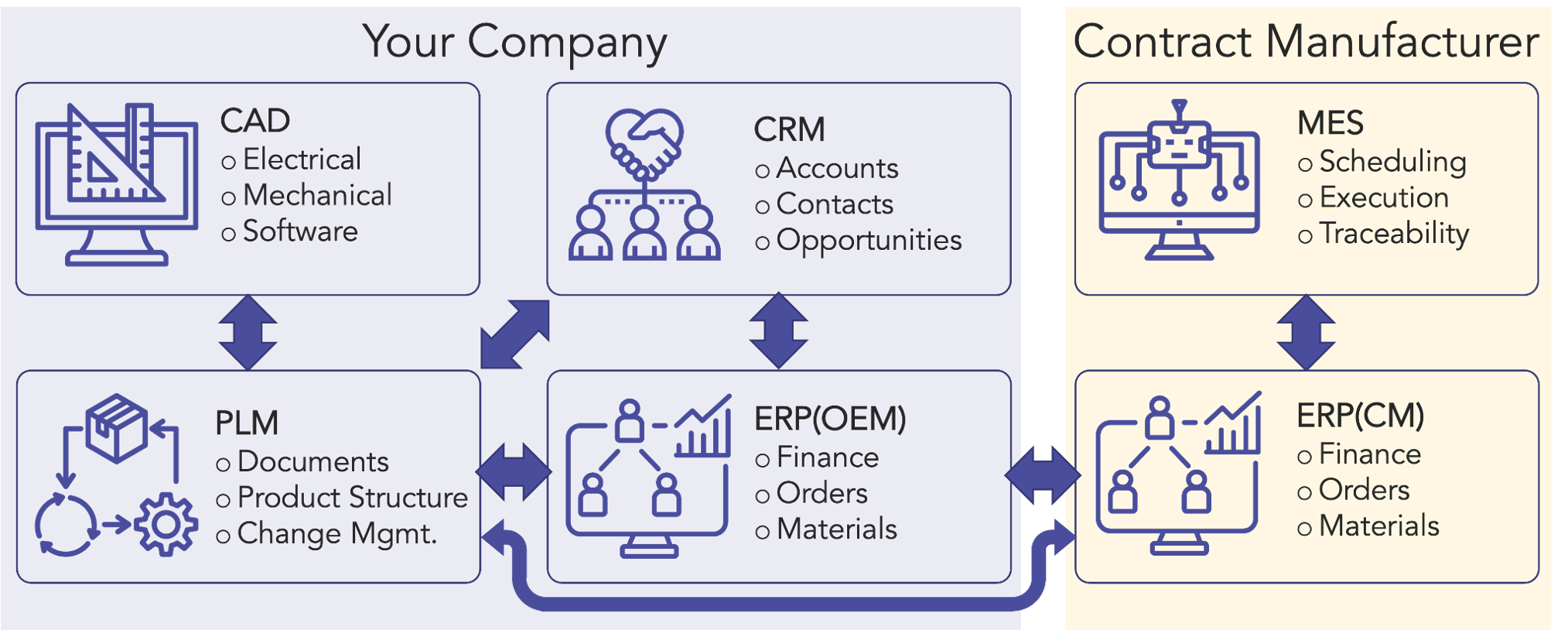

Leveraging SaaS / Software Applications and Tools – see the whole blog here

As you scale your business, you will find that managing data in different silos (e.g. engineering, finance, operations, sales, etc.) will become more challenging to manage over time. Companies that do not have a strategic business systems plan in-place, may encounter the following challenges:

- Silos of isolated information (e.g. the same information is duplicated across functions)

- Ineffective change management process resulting in product defects and higher costs

- Inability to create accurate reports and accountability metrics

- Risk of data being lost because it is on individual systems – dependence on “tribal knowledge”

- Manual and error prone data entry

- Data that is not accessible or usable

- Poor communications across functional groups (e.g. engineering, manufacturing, procurement, etc.)

- Lack of data integration between systems

While these issues may seem daunting, they are common among startups and smaller companies that have invested in specialized software for design engineering, accounting, purchasing, etc. But have not made the investment for larger software applications and business systems.

The benefits of having a strong systems deployment and integration plan include:

- Single source of “truth” for product data

- Effective Engineering Change Order (ECO) / management process

- Better reporting to support business management as well as regulatory compliance

- Reduced manual entry, associated errors and costs

- Support of ISO, FDA, and related quality management processes

- Automated workflows

- Clearer communication across functional areas and geographies

- Supports a stronger innovation ecosystem/culture

Mike Freier is Founder and Principal Consultant at the Product Management Consulting Group Inc. He has 20+ years of experience with high-tech companies, including more than a decade in product management and product marketing. He was a long-time board member and President of the Silicon Valley Product Management Association, served on the MIT-Stanford (VLAB) executive planning committee and spent several years mentoring start-up founders at the Cleantech Open. Mike graduated from the University of Massachusetts at Amherst with a BSME degree.